AN EFFICIENT SYSTEM INSPIRED BY NATURE

Geothermal systems are inspired by the extraordinary efficiency that we can find anywhere in nature. Buildings are powered by the ground through a virtuous circle of energy withdrawal and release: just as a tree obtains vital energy from the earth through its roots.

The main features determining the efficiency of a geothermal system are:

- the quality of the design and installation

- the quality of the heat pump. Therefore our choice to install the most reliable heat pumps on the market, referring to Nibe Swedish technology

- the type of heat source and its temperature

- the type of distribution system and the temperature required for its operation

- the appropriate management of the system.

GEOTHERMAL SYSTEMS

Different types of systems

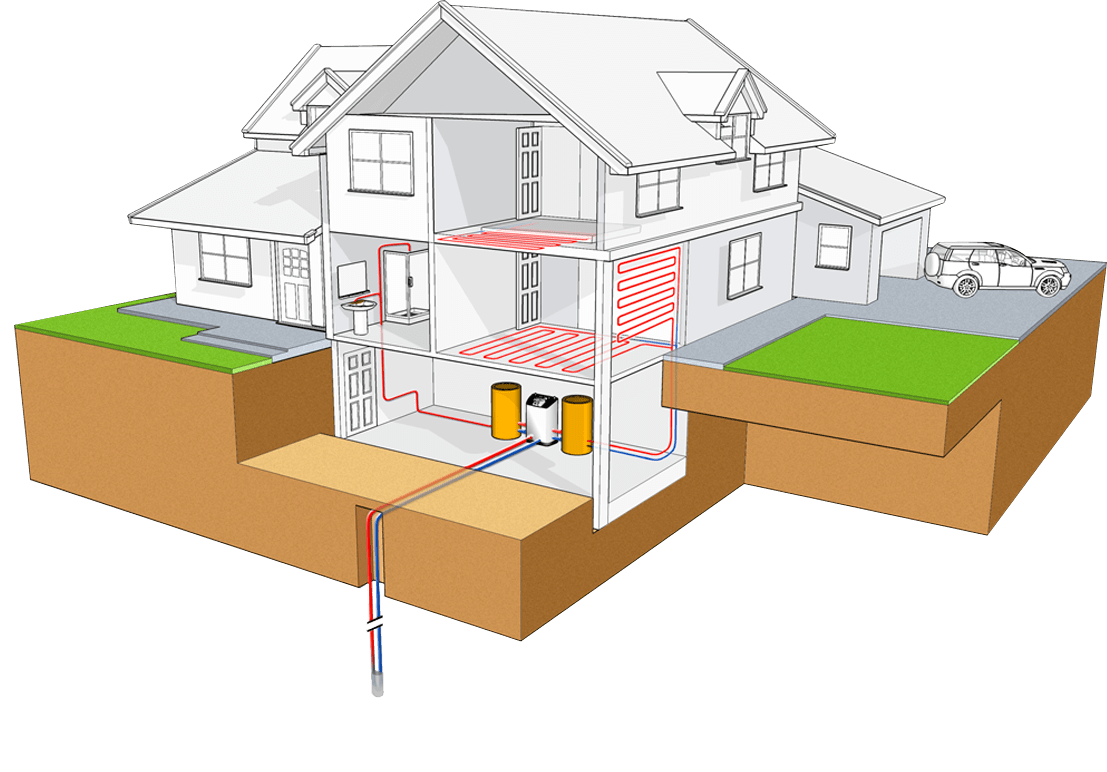

VERTICAL CLOSED-LOOP SYSTEMS

(GROUND-TO-WATER)

This system is the most reliable and used, as it benefits from the fact that beneath a depth of 10-15 meters the ground temperature remains stable at around 10° C throughout the year. Harnessing this constant energy allows for the best efficiencies, both in winter for heating and in summer for cooling.

The geothermal boreholes, which are 100/150 m deep on average, are only 15 cm in diameter. Geothermal probes consist of 2 or 4 U-shaped pipes that descend and ascend in a closed circuit containing a heat transfer fluid.

The extent of the probe field (the set of geothermal probes) is sized according to the energy demand of the site concerned.

Further details

These systems consist of high-density polyethylene pipes that exchange heat with the ground by closed-loop circulation of a heat transfer fluid (water with glycol). The average depth of the boreholes (about 100/150 meters) is determined by several factors, mainly geological or hydrogeological, as well as by the availability of surface area outside the building adequate for the purpose.

Geothermal probes, consisting of 2 or 4 U-shaped pipes that descend and ascend in a single circuit, are lowered into the borehole; ballasts attached to the probe bottom are often used to facilitate their descent. Once the probe has been laid, a specific premixed product of bentonite cements is injected from the bottom of the borehole, in order to saturate the spaces and create the best conductivity between the fluid circulating in the probes and the surrounding soil. This also prevent to connect aquifers crossed by the borehole. If the field consists of only one probe, this will be connected directly to the heat pump. In case of several probes, these will converge into a geothermal manifold, through horizontal connections laid about 1 meter below ground level, and hydraulically connected to the heat pump.

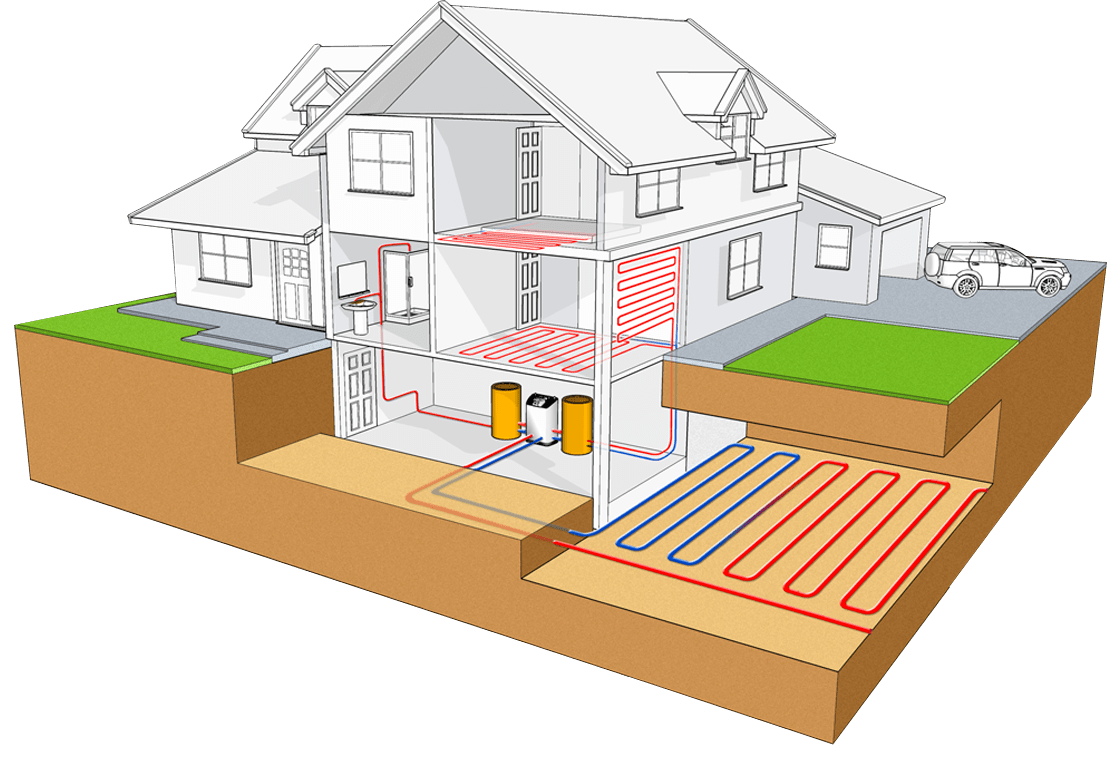

HORIZONTAL CLOSED-LOOP SYSTEMS

(GROUND-TO-WATER)

When a large area adjacent and external to the building is available, a horizontal closed-loop system can be considered.

This choice keeps the initial cost for the probe field low, as the use of specific machinery and equipment is not required. The probes are laid at a limited depth: as a consequence, the system will be inevitably affected by seasonal fluctuation in soil temperature. Nevertheless, good efficiency can be achieved with this solution.

The green area where horizontal probes are laid, roughly double the area to be heated in the building. It takes about 25 square meters to draw 1 kW.

The main advantage over the classical vertical-probe solution is the lower cost incidence referred to the realization of the geothermal probe field.

Further Details

In this system, the probe field is developed horizontally with the laying of PE pipes arranged according to different configuration. In this solution as well, several circuits converge in two supply and return manifolds, from which the connections with the PDC start.

Normally, horizontal pipes are laid at a depth of about 1.5 meters from ground level to remain well below the possible freezing level of the ground.

On the other hand, the following disadvantages should be considered:

a less performing system because of efficiency affected by outdoor temperatures;

not recommended for summer cooling. if combined with a high-temperature distribution system, it must be appropriately oversized;

on the area where the probe field is located, it will not be possible to build, pave, plant tall trees and evergreens.

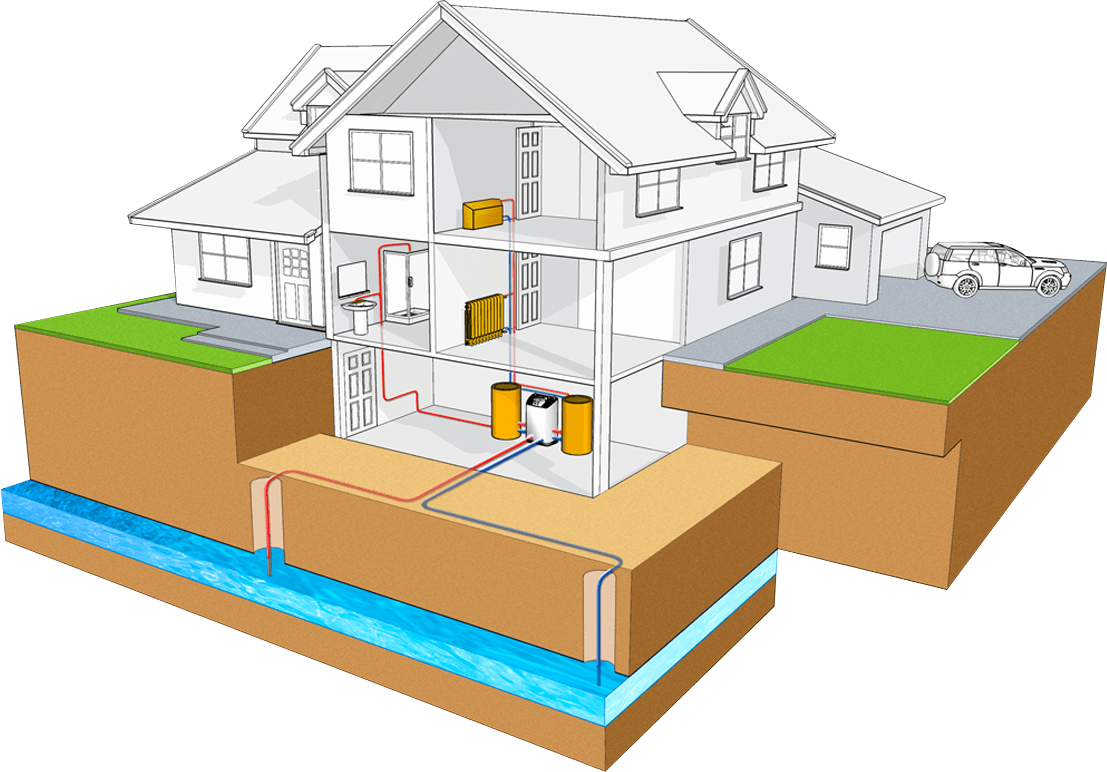

OPEN-LOOP SYSTEMS (WATER-TO-WATER)

The use groundwater directly as the primary heat carrier is possible in geographic areas where stable, shallow aquifers are available, a very common condition in the Po Valley,

Hydrothermal, open-loop, or water-to-water systems are advantageous in terms of efficiency, as the temperature of the groundwater is normally constant throughout the year. The initial costs of setting up are also greatly reduced, especially for medium- or large-scale plants.

The water withdrawn and used in the system is not chemically altered in any way, and therefore can be returned to the aquifer.

The biggest advantage of the water system over the probe system is the initial investment, which is significantly lower.

Further details

Unlike the fluid temperature in a “closed loop” where there is a physiological seasonal drift, in a groundwater geothermal system the heat transfer fluid has a constant temperature all year round. This advantage is proportional to the installed power, thus greater for medium and large buildings. In this case, thermal withdrawal is carried out through one or more wells, versus the need to drill more boreholes at relevant depth to develop all the linear meters required to achieve the same results. Groundwater used to operate the plants is returned to the water table or to a surface drain. It is not chemically altered in any way. It yields or assumes a delta of about 4°C in relation to the use of the heat pump for heating or cooling, and it can then be reused for other uses (irrigation, sanitation, etc.). In absolute terms, the open-cycle system is the most efficient and achieves very high values in coefficient of performance (COP).

This solution requires a careful examination of the hydrogeological structure of the area concerned, verifying the sustainability of both withdrawals and re-injections, and considering authorization processes.

In geographic areas where there are stable aquifers at limited depths (0/50 m depending on the size of the building), groundwater can be used as a thermal carrier. Areas near rivers, lakes or rice fields, and lowland areas in general, normally have the features required for developing this type of solutions, also often found in urban areas. Just to mention some well-known examples in Turin, the Egyptian Museum, the Intesa SanPaolo skyscraper, and Green Pea are all heated / cooled with groundwater systems.

The use of groundwater can be done in two distinct ways:

- Groundwater extraction and disposal to surface water body

- Groundwater extraction (withdrawal well) and subsequent re-injection into another well (dispersant)

In both cases, we speak of an open circuit, with two major advantages in terms of system efficiency:

- The water temperature is higher than in probe circuits: normally 10°/14°C is encountered, but it is not uncommon to reach as high as 16°C.

- Unlike the fluid temperature in a “closed circuit” where there is a physiological seasonal drift, in a groundwater geothermal system the heat transfer fluid has a constant temperature all year round.

These two factors directly contribute to better performance of the heat pump, but on the other hand, in this type of plant, the presence of a pump in the well determines additional electrical consumption. Because of this last aspect, it is not energetically convenient to tap into deep aquifers.

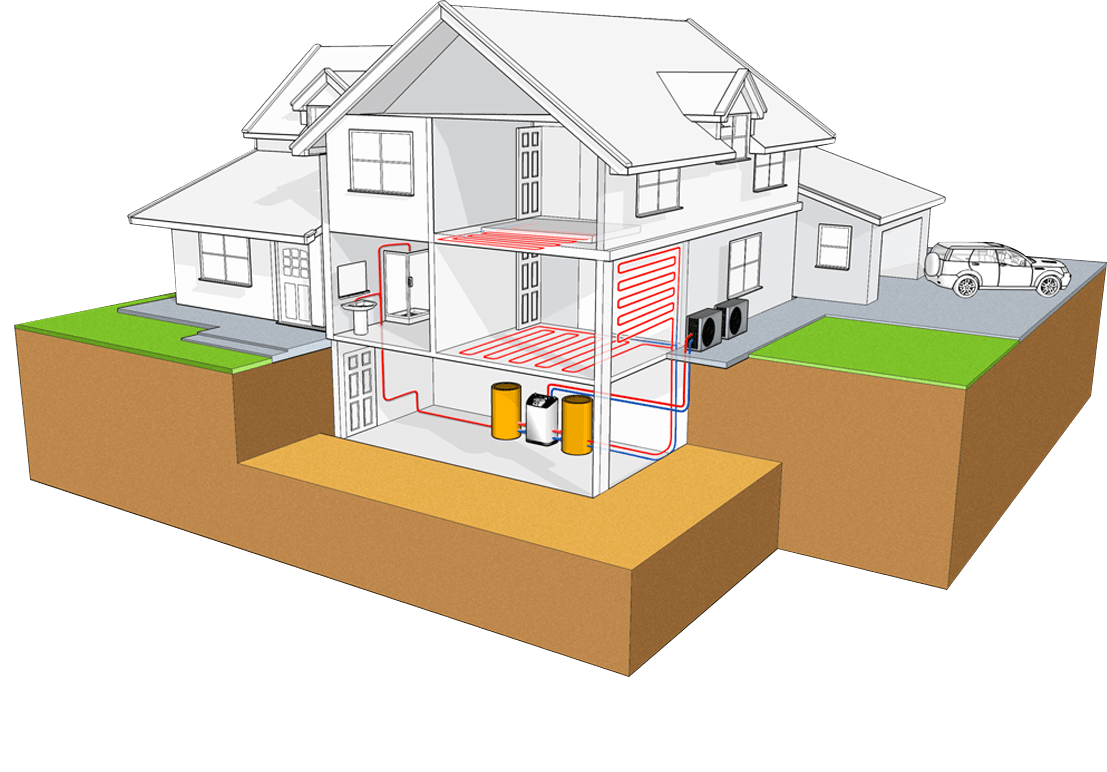

AIR-TO-WATER SYSTEMS

A possible alternative solution to the above mentioned systems is the installation of a high-efficiency air-to-water heat pump, which provides significant energy savings over a traditional system.

In fact, even outside air can be a source of thermal energy. These systems are characterized by efficiency levels, and therefore operating costs, that are not comparable to those of geothermal systems. On the other hand, the initial investment required is significantly lower. They are particularly suitable for buildings with low consumption, limited use, or located in areas not accessible to machieneries necessary for drilling.

Further Details

Just as the previously described systems, aerothermal ones are able to provide heating, cooling and DHW with one solution.

The heat pumps we use in our aerothermal systems belong to the most recent generation of “hydronic” machines. These are composed by an external unit including the condensing component. In this case, the connection with the technical room (where the storage tanks are located) is only hydraulic and not part of the refrigeration circuit.

These solutions are particularly suitable for buildings with low consumption, limited use (holiday houses) or budget, or where drilling is not possible.

If the pillar of geothermal heat pump systems is the constant temperature of the heat carrier (water/probes) throughout the year, the disadvantage of air-to-water alternatives consists precisely in the inconstancy of the temperature of the heat carrier (air).

The heat pump is required to generate heat during winter, therefore using cold air; and to produce cooling in summer when it is warmer. Technically the purpose is still achieved, but obviously the efficiency and operating costs are not comparable to those of geothermal systems.

This limitation is partly offset by the very low installation costs.

Choosing high-quality aerothermal heat pumps, however, it is possible to totally replace traditional systems, achieving benefits and savings in annual operating costs, especially as an alternative to LPG or oil boilers.